System 800xA

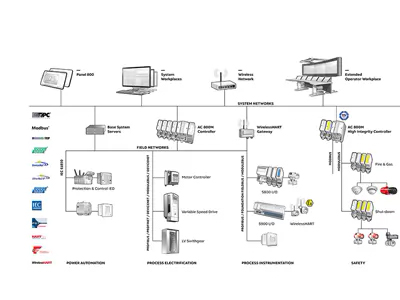

The new release of System 800xA brings major value to capital projects with more flexible and efficient engineering and an enhanced scalability of the system.

System 800xA provides significant innovations to the entire system architecture and introduces key technologies that shorten project execution time, facilitate late changes and enhances the scalability of the system bringing substantial value to capital projects.

Efficient Engineering

The Select I/O is an Ethernet based single channel I/O that is designed with parallel project execution in mind. Together with the new concept; xStream engineering it will reduce the project time by “de-coupling” automation tasks from each other. Two independent teams can work in parallel and then bind together with precision and efficiency later. This reduces the impact of changes during the project and effectively reduces the commissioning time. Testing efforts and the hardware footprint are considerably reduced as well.

Flexible I/O Solutions

The new System 800xA Industrial Ethernet I/O Network brings the remaining hardwired I/O into the system via a standard and future-proof ethernet network. All available I/O options, including fieldbus technologies, serial protocols and hardwired I/O, work together seamlessly in a single control system communicating to all types of devices smart or not.

While fieldbus technologies have long enabled online configuration, provided access to diagnostic data and supported “soft” marshalling and late binding, the new System 800xA single channel Select I/O brings these same benefits to hardwired I/O. This includes utilizing the same ethernet I/O network to seamlessly integrate traditional S800 I/O.

Increased Flexibility and Scalability

System 800xA’s hardware is equally effective for small hybrid systems as for large, high availability, integrated automation applications, the modularity of the subsystem results in higher return on assets by providing the flexibility to choose the specific functions necessary to meet actual requirements. System 800xA 6.1 includes native support for cost effective S500 I/O as well as two new safety controllers; PM857 and PM863. These additional High Integrity controllers offer flexibility of network design as they can be used for integrated yet separate safety operations or for fully integrated applications where safety and business critical process control are combined in one controller without sacrificing safety integrity.

IEC 61850 Edition 2 brings engineering efficiency

One of System 800xA’s extended functionalities is the Electrical Control, the ability to integrated and allow for seamless operation of power generation, protection and electrification related devices is unparalleled.

The new version supports the IEC61850 Ed 2 and reduces cost in the project execution through optimized engineering and deployment. It's now easier to configure and integrate IEC61850 networks within System 800xA’s engineering environment. Everything can be engineered in the System 800xA Plant Explorer. It has the ability to import any vendor’s SCD file, which defines the electrical network, without the use of multiple separate engineering tools or applications. This reduces the engineering effort and complexity in managing these interfaces while reducing costs maintaining these types of solutions.

All Rights Reserved. Microsystems.